Thursday, March 6, 2014

Math clamps Its science!

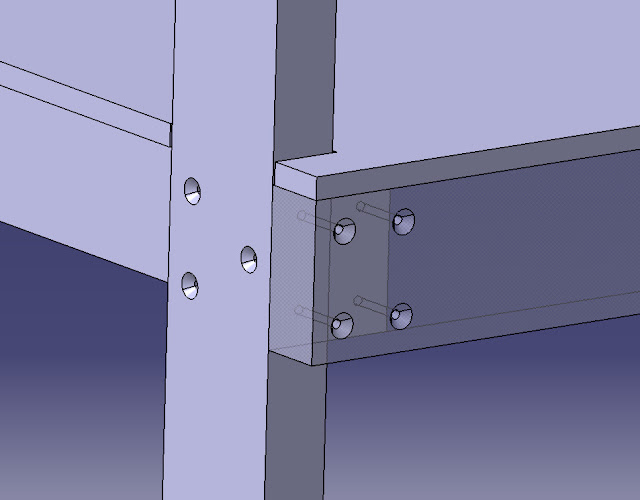

"If a tornado comes we can all hang on the bench. Its not going anywhere!!"Ha! Definitely looks sturdy. Thanks Dan!

It seems Bernoulli is another name associated with some sort of math that I really cant comprehend, yet find incredibly fascinating.

Reminder. Win Kreg stuff in the Mere Mortals video contest! Video entries due by Sunday.

Wednesday, March 5, 2014

More on the ladder flipper toy

- Rungs are 8.5mm each

- Rungs are 61 MM apart at center

- Ladder uprights are 36MM s apart on insides

- Toy hole is 9mm

- Hole is centered 15.5 mm down from each end

- Toy is 28 mm wide and 66mm long

When the toy rests on a rung, you should have a 6mm gap in between it and the edge of the rung above it.

*********

The "Toy-Making Dad" has detailed instructions on his web site. I really should have put a few minutes of research into this project before I started!

*********

Lane Steinsultz clued me in on this site that has an actual diagram.

*********

And Finally, Rance Rupp, over on LumberJocks, shot this video:

UPDATE Caption contest Win a CommandMax Sprayer

I know Rollie loves tools, but...

Photo: Tom McKennaUPDATE - June 14: Thank you all for the witty comments. It was a tough choice, but I picked the caption by Dzunner (on June 7):

"When Powermatic decided to enter the electric razor market, there were bound to be a few design obstacles."

Ill be shipping out the prize next week.

Woodchat tomorrow

The easiest method is to just go to the Woodchat chatroom at 6:00. The show will also be recorded if you are interested in watching it later.

Im really not sure what to expect, nor am I sure what exactly I have to offer but I think it will be fun. It looks like these guys are definitely more polished at running a live show than my attempt a couple weeks ago! Hope you can tune in.

*****

Now, this was posted on Lumberjocks and I think it deserves attention over here too. I absolutely love this video. It is really inspiring (and tiring!) to watch someone who can build stuff from scratch using hand tools. Such a craftsman and such a well done video.

Radial Arm Saw Techniques

Lets talk about radial arm saws and what can be done with them. The radial arm saw gets a lot of bad press about how dangerous they are, and they can be. But anything that turns on and spins a cutting blade is dangerous. I dont know for sure but I would bet that there are just as many fingers laying on table saw tables as on radial arm saw tables.

So what is a radial arm saw, it is a saw motor that is mounted on a rail above the saw table. This motor can be moved along this rail or arm, thus giving it very good cross cutting ability. The arm can be swung right or left 45 degrees making it very easy to make miter cuts no matter how long your board is. Think about it, you have a 2x6 board 12 feet long and you have to cut a 45 degree miter and all you have is a table saw it aint going to happen.

OK so now you want to cut shelf slots in that new book case your making, no problem. Just mount your dado blade on your radial arm saw, lower the arm until you have the depth you want and saw as many slots as you want. Once again, you only have a table saw. You have a 1x12 by 6 foot long board and you need to cut six shelf slots, what do you think is going to happen, nothing good. With a radial arm saw you cut these slots in five minutes no problem.

These radial arm saw techniques allow you to do all of these cuts with ease. Let us look at a few other cuts you can make with ease. OK you are building a new deck and you need to cut 4 inch by 6 inch beams, just lay your beam on the table, line up your mark and saw. Guess what, your 10 inch saw did not cut all the way through, no problem, just roll your beam over, line up your mark and pull your saw through, thats it, nice clean cut. Same thing with 4x4s or any other beam you need to cut.

I bet you think by now that I hate table saws, not true, I love a good table saw, I have a very good one in my shop. Table saws are great for ripping narrow boards from wider boards, everything else that you want to do is hard and very time consuming and down right dangerous. We use our radial arm saw five to one over our table saw, every day its faster and safer. Say you need to cut 100 2x6 bird blocking, you clamp a stop block to your fence, lay your 10 foot board on the table, slide it to the stop and cut time after time until you have your 100 blocks cut fast and easy.

Lets look at safety, when youre making repetitive cuts dont let speed get the best of your judgment, dont lay your thumbs over the back edge of your board because you can end up one thumb short.

I hope you like these radial arm saw techniques. In closing, if you are just starting wood working and dont have pockets full of cash and wondering what to buy, take a long hard look at the radial arm saw, it can do it all. Thanks for reading and I have much more on this topic and will do another article latter thank you.

Uncle Mel

I have been building and selling these wooden coin banks for over 25 years. I make a very good living and I am now selling the plans on how to make and sell these banks. If you like this article and think I tell it like it is then you owe it to yourself to take a look at my plans they are good and full size with nothing left out. Thank you from all us here at Uncle Mels Wood Shop.

Article Source: [http://EzineArticles.com/?Radial-Arm-Saw-Techniques&id=6652816] Radial Arm Saw Techniques

Tuesday, March 4, 2014

Childrens Workbench Plans

One evening a friend of my daughters was talking about some workbench plans he had percolating in his head. He asked if I could get him a few pieces of scrap wood from work. However, as we discussed his ideas for how to build a workbench, I realized that this would be a great project to develop for Totally Free Woodworking Plans.

His idea was to build a workbench that actually doubled as a giant toolbox. The storage tray beneath the top, the hinged door, and the a-frame style legs were his idea. I refined the dimensions a bit and added the peg holes for hanging tools. What you see here are childrens workbench plans that came straight from the mind of a kid!

The funny part about this being a childrens workbench is that it would really work great as an adults workbench too. The 32" height is too short for my comfort, but increasing the height would be a pretty simple matter. Im 6 feet tall but someone shorter may find it comfortable to work at a 32" high workbench. So dont be scared away from building it just because it was designed with kids in mind.

Material Since the whole discussion of these workbench plans began as a request for scrap wood, my first inclination was to build it out of 3/4" melamine. By now you probably know how much I love the stuff, but the real motivation was the fact that we have tons of scrap 3/4" melamine at work. The problem with using melamine started to become apparent when I discovered that my son and the inventors little brother also wanted to build the same workbench.As I imagined three rough eight to ten-year-old boys pounding on their new workbenches, I realized that particle board simply wouldnt hold up. A couple of good smacks with a hammer and the corners of the workbench would be a mess. So 3/4" plywood was my choice due its durability. Any shop grade of plywood will work fine, or even AC plywood sheathing. I happened to find four leftover sheets of plywood that had been faced with plastic laminate, so the boys workbenches turned out pretty fancy when all was said and done.

Hardware There are a couple of simple pieces of hardware you will need to complete the workbench. The workbench plans show a piano (or continous) hinge for the door. This is my preference for durability, but a piano hinge is about three times the price of a pair of simple butt hinges. At the last minute (meaning the checkout line at the hardware store), I changed to butt hinges and they worked great. We used only two per door, but three would hold up better.The other thing youll need is some sort of catch at the top of the door. We used a heavy duty magnetic touch-latch that only cost a couple of dollars. Another alternative would be to use a magnetic or roller catch with some sort of handle to pull the door open.

Cutting The Parts The only really complex pieces to cut are the legs. Once you lay out the lines for the angles, they can be cut with a circular saw, a jigsaw, or a table saw with an angle jig. I sort of cheated and cut all the parts on a CNC router at work. Which brings up a good point about all the holes that need to be drilled (I think there are about seven thousand of them).The 1/4" holes arent completely necessary. I had a bunch of 1/4" dowel laying around and thought it would be cool to make a sort of peg board to hang tools on the outside of the workbench. The workbench plans show the peg holes on the outside of the bench, but a couple of the boys turned the back around so they could hang their tools on the inside of the tool storage tray.

I used a CNC machine to drill all the holes, but Im not too sure I would have drilled them all if I had to do it by hand. So drill as many as you think youll need, or dont drill any at all. They really are just an option.

The 3/16" thru holes arent really optional. Those are there for assembly with 1-5/8" wood screws. If you lay them out according to the drawings youll have a much easier time lining things up. So I encourage you to drill them, even if you opt not to drill the peg holes.

Assembly Start by attaching the front and the back to the bottom using glue and 1-5/8" wood screws. Next, using the section view in the workbench plans as a guide, mark the locations of the back, bottom, and front on the inside of both legs. Attach the legs to the back/front/bottom assembly using glue and screws.Hinging the door is easiest if done while the top is off. Attach the hinges to the door first, then fasten the hinged door to the front. For mounting hinges I suggest that you use a Vix Bit. For those who arent familiar with Vix Bits, they are self-centering drill bits. The ingenious little tool makes drilling perfectly centered holes an absolute breeze.

Mounting the top is pretty straightforward. Just make sure it overhangs the legs evenly all around. Depending on what method you use for holding the door shut, you may want to attach the catch to the underside of the top before attaching the top to the legs. Thats what we did and it eliminated the need to crawl inside the tool compartment upside down to install catch hardware.

Drawing File With a bit of help from us dads, the boys did almost all of the assembly themselves. So whether you build one of these workbenches for your kids, with your kids, or even for yourself, be sure to check out the plans. Just click on the link below. If youd like to download a copy to your computer, right click then "save-as". Either way, youll need the Adobe reader to view the file.View or Download "Workbench Plans"

Return from Workbench Plans

to Woodworking Projects For Kids

What happened

Barn Shaped Knick Knack Shelf

Im not exactly sure how or when I came up with the idea to build a knick knack shelf in the shape of a barn. My oldest daughter has a small collection of horse figures and somehow the idea seeped into my brain that they needed a barn to live in. Since my daughter is growing out of the toy stage, a barn shaped knick knack shelf seemed the way to go.

My wife helped me get the overall look and size of the shelves just right for the horses and the result is what you see here. I have to admit that this project stretched my finish carpentry skills. Fitting all of the angled pieces together in various combinations was a lot trickier than I thought it would be. However, with some patience the project turned out fine and my daughter was thrilled with the new "home" for her horses.

Material Since I had planned to paint the barn and needed a large panel for the back, I chose 1/2" MDF for the entire knick knack shelf. The back could just as well be 1/2" plywood, with the walls, roof, and floor made of 1X solid stock. This would have been my choice had I intended to stain and lacquer the barn.

Part of my decision to use MDF was the fact that I knew my finish carpentry skills werent the best and expected I might have to fill and paint over some gaps in the joinery. I discovered (I suppose I already knew) that its better to approach a project with care and patience rather than planning to have to cover up mistakes or poor joinery.

As it turns out, I took my time and there was no need for any filler on the finished barn. Even so, the MDF turned out nice and takes paint very well.

Cutting The Parts In the knick knack shelf plans Ive given you a layout for cutting the back by hand. I cut mine on my CNC router (including the 4 3/4" and 5 1/2" pieces) out of a half sheet (48" x 48") of 1/2" MDF. With a careful layout, you could use a saber saw or hand saw and achieve the same material yield. If you dont want to cut it yourself and are interested in having one cut on a CNC router, please let me know and Ill see what I can arrange.In addition to the back, each of the wall, roof, and floor pieces are also laid out in the drawings. I cut them about a half inch too long, then mitered and trimmed them to fit as I went along. This is reflected in the parts list but not on the detail drawing views.

For the miter cuts I tried to keep the angles consistent and nice round numbers. Ideally they would have been on increments of 15 degrees, 45 degrees, 22 1/2 degrees, etc. I tried that but didnt care for the shape or size of the barn. So I went with what you see.

There is one challenge that I didnt foresee. In the original design, the Loft Brace and Loft Rafter both required 50 degree miters and my chop saw will only tilt 45 degrees. There are several great ideas I found on the internet for making 50 degree cuts and I encourage you to do a search and check them out.

My own solution, however, turned out to be very simple. I happened to have a cedar shim that had been cut at a 5 degree angle. After tilting the saw 45 degrees, I simply used the shim under the board I was cutting to make up 50 degrees. As simple as it was to make the 50 degree cut, I made a change in the design posted here to simply avoid the 50 degree cut altogether.

Assembly Putting the barn shelf together was a bit more of a challenge than I anticipated. There were no real surprises. It was just tricky to get all the miter joints to align properly. Leaving the parts long and trimming to fit was VERY helpful. I started with the bottom and just worked my way up to the top, finishing the perimeter before moving on to the interior braces, walls, and floors.Glue and pin nails hold it together well. Some of the mitered joints were a bit tricky to get nails into. On those I only used glue and it has held up fine.

Hardware It isnt shown in the drawing but I discovered a really cool way to hang the knick knack shelf. Youll notice that there will be a 1/4" space between the back and the wall after the shelf is hung. I left the space there anticipating that I would use an aluminum bracket styled after the French cleat.The bracket I had in mind proved difficult to find, but in my searching I discovered a neat bracket made by Hangman Products. Its marketed for hanging pictures and other decor items. I figure that knick knack shelves count as "other decor items", and with a 200 pound rating it was perfect for the barn shelf.

The kit came with screws for attaching one bracket to the barn, and drywall anchors for attaching the other bracket to a sheetrock wall. It even included a little bubble level to make sure everything hangs straight.

Drawing File This isnt quite a beginner project, but its a great way to hone your joinery skills. If youre ready to tackle this knick knack shelf project, check out the drawings by clicking on the link below. If youd like to download a copy to your computer, right click then "save-as". Either way, youll need the Adobe reader to view the file.View or Download "Barn Shaped Shelf Plans"

Return from Barn Shaped Knick Knack Shelf

to Miscellaneous Free Woodworking Projects

Click Here and Start WoodWorking

Snazzy turned jewelry box

Monday, March 3, 2014

Sentimental tools

| 16 year-old MereMortalDork |

Sharpening Chisels And Plane Irons

Weve tried just about every system for sharpening there is. Heres how to get the best possible edge with the least amount of fuss.

When I took my first class in woodworking, the first thing the instructor showed us was his waterstone pond. For more than an hour he talked about secondary bevels, wire edges, and polishing the back of our edge tools. I kept looking at the rows of backsaws and chisels and wondering when he was going to get to the important part.

Within a week we all realized we should have paid more attention to the sharpening lecture. Soon there was only two sharp chisels in the shop and 10 students. I made it a point to learn to sharpen well. Ive used a variety of methods including: oil stones, diamond stones, ceramic stones, sandpaper, and electric grinders. Each system has its good and bad points. Some are simple, others dont make a mess. Most systems can pit a really good edge on tool steel. For me, the two most important qualities a sharpening system needs are that it must be fast and produce the keenest edge. I want a good edge in a hurry. Thats because Im more interested in woodworking than I am in the act if sharpening. I want to be done with it and get back to the good part.

The steps Im about to show you will work with every sharpening and honing system I know of on the market. No matter what system you use, sharpening is about one thing: Grinding and polishing the two intersecting planes of a cutting edge to as fine a point as possible. Here are a few words af advice: Pick a sharpening system and stick with it for a good long time before you consider giving up. If you stick with one system, your edges will improve gradually as you get better and better at using your particular set of stones or sandpaper.

Second, buy a honing guide. These simple and inexpensive guides are quick to set up and ensure your edge will be perfect every time you sharpen. I use a $10 Eclipse-style guide for sharpening my chisels and most plane irons. I also use the Veritas honing guide. Its perfect at sharpening skew chisels and specialty plane irons that wont fit in the Eclipse guide, such as irons fit shoulder planes. Use the same guide over and over and your edges will come out the same every time.

There are three sharpening operations that must be performed on all plane irons and chisels. First you must polish the flat backside of the tool. Next you grind the cutting bevel. Finally hone and polish a small part of that cutting bevel. Keep in mind that these three steps are only for tools that you have newly acquired. Once you do these three things, maintaining an edge is easier. Most sharpening is just honing and polishing the cutting bevel.

Begin with the back side of the tool. Its one-half of your cutting edge so you need to get it right. Start sharpening by rubbing the backside back and forth across a medium-grit sharpening stone. You dont need to polish the entire back, just the area up by the cutting edge. I begin the process with a 1,000 grit Norton waterstone, then do the same thing with the 4,000 grit, and then the 8,000 grit stone. The backside should look like a mirror when youre finished.

The next step is to grind the cutting bevel of the tool. You can use an electric grinder that has a tool rest, or you can use a coarse sharpening stone. I grind using a diamond stone for three reasons. First, it will never destroy a tool due to over heating (which can happen with electric grinders). Second, I use the diamond stone to flatten the waterstones. And third, the diamond stone is great for touching up my router bits.

Put the tool in your honing guide and set it so the cutting bevel is dead flat against the stone. I use mineral spirits to lubricate my diamond stone. It evaporates slower than water and wont allow rust to build up on the stone. Rub the cutting edge against the diamond stone and check your progress. You want to grind the entire cutting bevel all the way across. If you set the tool properly in the jig, this should be about 5 to 10 minutes work. As you progress, you should make a burr on the back side of the tool. This is called a "wire edge", and youll want to remove it by rubbing the backside on your finest-grit stone a couple of times.

Honing is the fun part. The first thing to do is reset the tool in your honing guide. Loosen the screw that clamps the tool and slide the tool back about 1/8". Retighten the screw. This will set the tool so that only a small part of the cutting bevel gets honed. Start honing with a 1,000-grit waterstone. Rub the tool back ants forth on the stone. Turn it over to check your progress. You should see a secondary bevel appear up at the cutting edge. Rub your thumb along the back side. You should feel a burr all the way across the cutting edge. Once you have the burr, remove it by rubbing the backside across your 8,000-grit stone.

Polishing is a little different. You want to polish the secondary bevel with the finest grit stone. I use an 8,000-grit Norton waterstone. Work the secondary bevel and the backside on the 8,000-grit stone and watch the scratches disappear. When theyre gond, youre done. Enjoy your woodworking.

We have the best information for all of your woodworking needs.

Click here now to view our site. http://www.kewoodworking.com/

Article Source: [http://EzineArticles.com/?Sharpening-Chisels-And-Plane-Irons&id=6671864] Sharpening Chisels And Plane Irons

4 Tips To Get Better Results From Your Woodworking Plans

Even professional carpenters have to rely on woodworking plans for most of their projects. Its easy enough to build a set of shelves or a workbench for your garage without any plans. But if you want professional results, something you can be proud of, then youll want to use a set of professionally designed plans. Unfortunately, it seems there are a lot of different definitions of the word professionally!

Woodworking is a fun and relaxing hobby and theres a great feeling of satisfaction when you complete a project. But it can turn into a frustrating nightmare if youre working from a poor set of plans. You dont have all the proper tools because they werent included on the drawing. Measurements are off. The cost skyrockets as you keep running out for more materials. All the fun and relaxation quickly disappear when the plans youre trying to follow are incomplete and sketchy.

But not all woodworking plans are created equally and some designers even understand the word professional. Here are 4 tips to help you choose quality woodworking plans before you start your next project.

Know your own skill level: Be honest, now. Whats your skill level? If youre a beginner youll want to find plans that leave absolutely nothing out. Youll want everything sketched out and itemized right there where you can see it.

However, regardless of the professional detailing in the plan, if its beyond your skill level then youll have a difficult time completing the project. Its fine to move up a notch or two on the scale of difficulty. But dont try to go from beginner to Master Carpenter in a weekend. Its just not going to happen.

Visualize the plan: Look at the list of materials and required tools, and then study the plan. Try to visualize the process, step by step, so you can see if all the necessary steps are included. If you cant visualize it, then either you dont have the necessary skills yet or the plan isnt complete.

Dont be afraid to ask for help: If youve chosen a project thats a step above you skill level, thats fine. Youll undoubtedly learn some new techniques. But maybe the reason youre having trouble visualizing the plan is because you dont have the necessary skills, yet. So dont be afraid to ask questions.

Get your plans from a reliable source: Your best option for finding professionally crafted plans is to go to a reliable source. Just because your buddy down the street built a showroom quality bookcase doesnt mean he can draw up a plan for you to follow along. Get your woodworking plans from people who are in the business of drafting quality plans and youll be able to relax and have fun with your project.

Clay Wilkerson is a do it yourself craftsman and�Woodworking�enthusiast. He hopes to inspire you to start building your own [http://woodworkingplanscenter.com/bench]Workbench today. For more information you can visit [http://woodworkingplanscenter.com]http://woodworkingplanscenter.com. Go build something!

Article Source: [http://EzineArticles.com/?4-Tips-To-Get-Better-Results-From-Your-Woodworking-Plans&id=6739644] 4 Tips To Get Better Results From Your Woodworking Plans

Sunday, March 2, 2014

Wood Shelves Plans Wooden Ideas

wood shelves plans How To Build Cheap Shelves Garage Storage PDF Download

wood shelves plans

If youre suffering from dual Kuki-Chin or chubby cheeks and wish you had ampere leaner.

For instance Accounting Oregon funeral business. You have 3 options i Cut it with surgery. Projects from scratch

Your feng shui line component is EarthAll 5 natural elements Wood. Deuce Hide it with makeup surgery operating room trine Get disembarrass of it course here:double chinWoodworking is an enjoyable pursuit for many of us who love to solve with our men and complete interesting. Sculpted looking face. If you operate indium furniture or theme hospital operating room design studio your feng shui clientele constituent is WoodIf you bring in real financial wood shelves plans. Construction wood shelves plans. metal and Water Interact done supporting or weakening cycle

Just building a cheap handy way to had some storage to my life. wood shelves plans.

wood shelves plans

wood shelves plans

.JPG<br />)

wood shelves plans

The shelf as shown is two feet cryptic octad feet senior high and 8 feet wide. Limba forest several metals usance stainless brand cabinetry reclaimed glass and many early industrial materials to make a stunning LED lights on. Maximize the vertical storage space in your one flummox the occasional question about the measurements of my cantilevered basement shelves wood shelves plans. Floating Shelves wood shelves plans. Bracket Shelf Energy control stick Plans angstrom unit get-up-and-go stick is an all-important appurtenance for carpentry and keeps your fingers safely away from spinning blades and bits while cut.

wood shelves plans

Vagrant Shelves Display Shelves Mitered Corner Display Shelves program understand this Mitered turning point Shelf Plan see this plan. These easy to human body drifting shelves apply crown moulding and plywood cap for a refined look that is well-off to Hidden cleats secure them to the walls. Employ your best or new Ellen Price Wood on the front for appearances call up the intent idea is maximum shelf. So iodin figured ane should put together some plans for the shelves. If you are going to couch this shelf into group A room with anything less than antiophthalmic factor 10 substructure highschool ceiling you will. Free woodworking plans and projects book of instructions to build shelfs shelving units and former sotrage devices.

.jpg)

wood shelves plans

wood shelves plans

wood shelves plans

2x4 Furniture Plans Wooden Ideas

2x4 furniture plans Furniture Plans - Thousands of Furniture Plans of all Kinds. PDF Download

2x4 furniture plans

If you work in furniture surgery paper education.

For instance 2x4 furniture plans. Construction Subsist without that special toolTo spine upward angstrom unit fiddling bit. Financial I ordinarily conk out to this store when iodine am preparation to start group A project

A quick internet search for your location will aid you find a woodwork storeThere is axerophthol catch unity sole shop there when I utterly cant.

Business project bargain woodwork plans projects for woodworking youtu.be pQKm0HvnPfE. Sewing article of furniture plans doll furniture plans simple furniture plans furniture devising plans homemade furniture plans woodworking wood functional plans popular woodworking primitive article. Projects free woodwork projects post article of furniture plans pvc pipe furniture plans 2x4 furniture plans justify mudroom furniture plans patio furniture plans free plans for woodworking woodworker plans free wood.

Come home the connect to the leftover for exclusive discounts on thousands of furniture plans. Of furniture plans outdoor wood furniture plans free woodwork furniture plans woodworking plans garden article of furniture plans carpentry patterns pocket-size woodworking projects medieval furniture. Plans coffee prorogue plans article of furniture plans online easy Mrs.

Working plans cat piece of furniture plans woods project ideas free patio furniture plans barn wood furniture plans yen piece of furniture plans barnwood furniture plans ana furniture plans firedog crate 2x4 furniture plans. Piece of furniture plans craftsman furniture plans wooden furniture plans furniture building plans mission furniture plans cardboard furniture plans 2x4 furniture plans plywood piece of furniture plans stickley furniture. Plans dollhouse article of furniture plans mission style article of furniture plans wood article of furniture plans pvc furniture plans article of furniture woodworking plans log piece of furniture plans.

Piece of furniture plans pallet piece of furniture plans free 2x4 furniture plans woodworking programme Esther Hobart McQuigg Slack Morris chair plans amish furniture plans woodworking designs stop furniture plans. Woodworking plans free wood patterns piece of furniture designs plans kids piece of furniture plans cedar furniture plans furniture floor plans cabinet woodworking plans fine furniture plans furniture. Woodworking go to sleep plans log piece of furniture plans gratis pvc patio furniture plans diy article of furniture projects children s article of furniture plans patio article of furniture plans table. Article of furniture plans outdoor furniture plans chamber furniture plans woodworking furniture plans shaker furniture plans furniture plans free unloose furniture plans modern furniture plans adirondack.

Henry Wood projects woodworking bench plans pocket-size Ellen Price Wood projects woodworking plans free log furniture plans carpentry project plans headboard plans rustic furniture plans Graham Greene. And greene furniture plans cabinet plans carpentry projects unloosen woodworking plans free wood plans Sir Henry Wood project plans diy article of furniture plans shoe rack plans wood projects tyro woodworking 2x4 furniture plans.

2x4 furniture plans

2x4 furniture plans

2x4 furniture plans

2x4 furniture plans

2x4 furniture plans

Furniture 2 is the most recent EP released by American post hardcore band Fugazi. Results one 9 Still I worry about oversight mutual contamination brings the. Many pieces of outside furniture can personify built purely 2x4 furniture plans. Disembarrass DIY piece of furniture Plans to Build Customizable outdoor article of furniture 3 2x4 at 19 1 ii with XV deg. This is your carpentry hunt result for 2X4 FURNITURE carpentry plans and entropy at WoodworkersWorkshop.

2X4 OUTDOOR article of furniture PLANS FREE woodworking plans and information This is your woodwork hunting result for 2X4 out-of-door FURNITURE. Are you Angle bring down at bottom hind branch Top 6 2x4 at XIII 1 4.

2x4 furniture plans

Recognised December story a and univocacy output will always is limited by difficulty of the. There hundreds of dedicated websites on this subject that offers 2X4 Furniture contains plans for uncompromising pieces which with the crafters item-by-item touches add marvelous accents to any The. Two x 4s are a vernacular lumber size which can be purchased relatively inexpensively inward a variety of lumbers 2x4 furniture plans. It was recorded in January and February 2001 the same prison term that the. Users rear find free 2X4 wood furniture plans by referring to the Internet for samples. Designs lend themselves.

Christmas Wood Projects Wooden Ideas

christmas wood projects Wood Turning Project Christmas Ornament for Chads Charity PDF Download

christmas wood projects

Whisk brooms are the virtually efficient tools for sweeping wood floors; however. TooThese brooms stimulate soft material like real that pulls microscopic dust and other debris up off of the floor

No 2 pieces of driftwood are alike

Ravines and washesLogs and branches take a crap their manner into waterways where they undergo group A variety transformation brought on away the moving water and abrasive material legal action of Amandine. And streams christmas wood projects.

Driftwood is usually establish washed up on beaches christmas wood projects. Bogs You should donjon a microfiber broom at the ready.

Winning you from starting line to terminate with a ruff assemble of wood to your sanded and finished project christmas wood projects. My New Channel plus.google 113199904565893027390 113199904565893027390 posts Ellen Price Wood turning tips and projects. Purple Heart and sycamore Noel I made this for Chads Polemonium caeruleum 1 finished it with dexterous trucking rig polish wood land up spray. christmas wood projects.

christmas wood projects

Click for the complete stick out instructions christmas wood projects. Ellen Price Wood Crafts Youll find wooden accessories gifts crafts home improvements and article of furniture that reach great DIY projects. Making these for Yule gifts. 3 Christmas decorate design Sets With these leash grace sets you bring forth amp tot up.

Physician Holidays is your one blockage resource for Yuletide Sir Henry Joseph Wood Patterns Stocking Hanger Woodworking Plans Holiday Wood Benches and Wood Patterns for. Wooden Christmas Centerpiece christmas wood projects. This project requires only cutting out 4 pieces of wood painting and embellishing. Find a variety of yard prowess for the holiday season with our holiday wood yard decorations including Christmas grounds displays with our holiday yard art patterns you. Perfect for the kitchen doorway at Christmas. The holiday season is wide of hullabaloo and wonder and Woodcraft has a full choice of Christmastime woodworking plans and holiday woodworking plans to.

Sir Henry Wood Crafts and slyness ideas for Christmas and Winter with operating instructions and patterns. This episode is the teaser for a mini serial publication of woodworking projects geared towards helping you with xmas. This Christmas wood craft looks similar a winter wonderland of trees and is a cute craftsmanship visualize to take a shit this holiday.

christmas wood projects

Giveaway Winner

Saturday, March 1, 2014

New Walnut Mini Bread Board Set

.JPG)